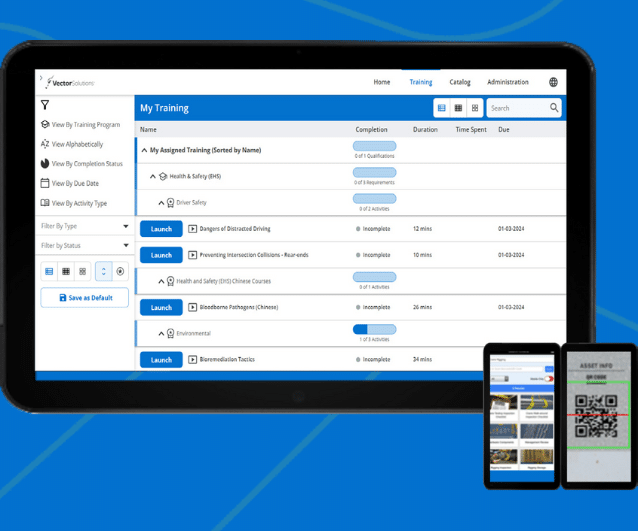

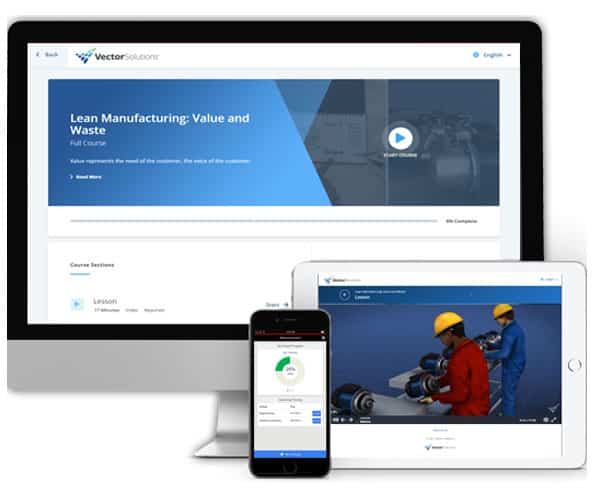

Online Industrial Skills Training for the Manufacturing Workforce

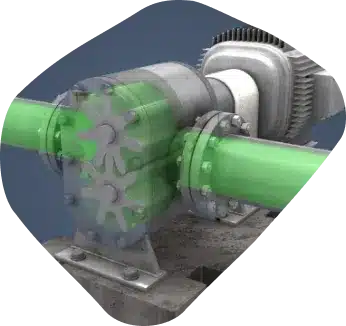

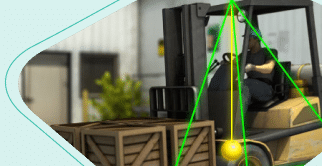

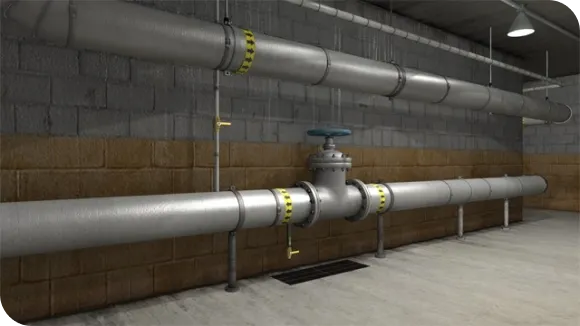

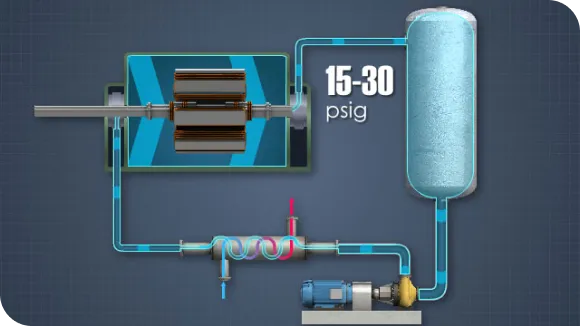

Increase job skills and retention of maintenance technicians, production workers, and machine operators with award-winning 3D-animated courses, mobile learning capabilities, and multilingual support.